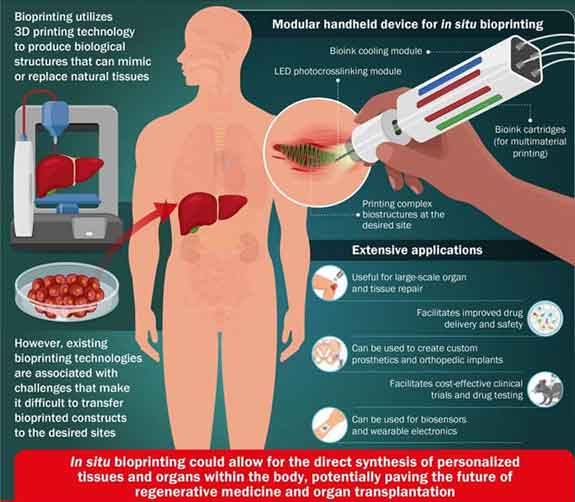

Welcome back. Although I’ve had surgery over the years, I know next to nothing about surgical procedures and even less about the technology. But I discovered that, in recent years, the technology includes in situ bioprinting. I was kind of amazed to learn that involves printing three-dimensional (3D) biocompatible structures and tissues directly within the human body.

The site-specific delivery of bioinks--solutions of biomaterials in hydrogel form, usually encapsulating the desired cell types--has emerged as a versatile technology for tissue repair and restoration of pro-healing constructs.

How did I get onto this topic? A recently published study of course. While bioprinting has made major strides in a short time, the study described an in-situ bioprinter developed to address some key limitations of current bioprinter designs.

Warning! To review the study and the new bioprinter, I can’t avoid getting technical, especially when I borrow directly from the study.

|

| Photo of bioprinting a multi-material construct on an artificially made pig skin wound (from Fig.2, iopscience.iop.org/article/10.1088/1758-5090/acc42c). |

The device is composed of: a printhead made with a high-resolution resin stereolithography 3D printer; pneumatic syringe cartridges adapted for hydraulic extrusion; a 3D printed cartridge enclosure; a mountable photo-crosslinking system composed of a 3D printed case with an array of 3 mm 405 nm light emitting diodes; and an array of external syringe pumps for hydraulic material extrusion.

|

| (A) Schematic of handheld bioprinter; (B) Schematic of device components; (C) Cross-sectional views (i–xii) and photos (xiii–xv) of different kinds of fibers produced with different printhead configurations; (D) In-situ multi-material bioprinting on a curved surface; (E) Bioprinted constructs produced on pig skins with different wound shapes; (F) Complex constructs produced using multi-material bioprinting (Fig 1, iopscience.iop.org/article/10.1088/1758-5090/acc42c). |

Bioprinter Capabilities

Multi-material bioprinting is achieved by means of multi-channel printheads with complex fluidic circuitry that enable flows of several bioinks in microscale.

A passive temperature control module maintains the temperature of cartridges for extended periods, allowing long-term printing of viscous bioinks.

The printer's efficacy in generating cell-laden fibers with high cell viability for site-specific cell delivery was shown by producing single- and multi-component cell-laden fibers. The multi-component fibers were able to model the invasion of cancer cells into adjacent tissue.

The versatility afforded by the modular assembly and range of printhead configurations allow fabrication of microfibers with diverse compositions and geometries. The researchers showcased the device by printing multiple cells, drug-releasing meshes and sensors.

The versatility of the device to produce biosensors and wearable electronics was demonstrated by incorporating conductive materials and integrating pH-responsive dyes.

The capabilities of delivering therapeutic agents was demonstrated by incorporating drug-loaded micro-carriers, extending the application of the printed fibers to on-demand, temporal and dosage-control, drug delivery platforms.

Wrap Up

The researchers judge that the handheld bioprinter can pave the way for a wide variety of applications in regenerative medicine, drug development and testing, and custom orthotics and prosthetics. In time, the technology could eliminate the need for organ donors, lowering transplantation risks.

|

| Printing customized tissues with a handheld bioprinter (from www.eurekalert.org/news-releases/992052). |

Older (2014) article on 3D bioprinting of tissues and organs in Nature Biotechnology journal: www.nature.com/articles/nbt.2958

Overview of bioinks for 3D bioprinting in Biomaterials Science journal: www.ncbi.nlm.nih.gov/pmc/articles/PMC6439477/

Study of handheld portable in-situ bioprinter in Biofabrication journal: iopscience.iop.org/article/10.1088/1758-5090/acc42c

Article on study on EurekAlert! website: www.eurekalert.org/news-releases/992052

No comments:

Post a Comment